Video

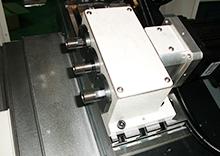

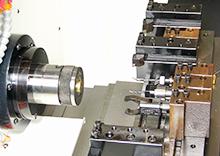

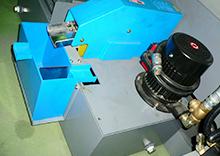

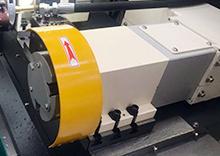

HCP-42 Turning & Milling Complex Type CNC Lathe

Specification

| MODEL |

Unit |

HCP- 42 (New Type) |

| Swing over cross bed | mm |

300 |

| Max. turning dia | mm | Ø250 |

| Max. turning length | mm | 150 |

| Hydraulic chuck | inch | 6" |

| Bore of spindle | mm | Ø45 |

| Max. bar feeding dia | mm | Ø42 |

| X-axis travel | mm | 340 |

| Z-axis travel | mm | 350 |

| X-axis rapid travel speed | m/min | 25 |

| Z-axis rapid travel speed | m/min | 25 |

| Spindle rotating speed | rpm | 20-6000 |

| O.D. turning tool size | mm | □20 |

|

I.D. turning tool size | mm | Ø20 |

| Coolant tank volume | L | 110 |

| Cutting coolant pump | HP | 1 |

| Collet type | -- | C44 / 173E |

| Spindle motor | KW | 3.75 (5.5 opt) |

| X/Z-axis servo motor | KW | 1 |

| Guideway type | -- | Linear guideway |

| Approx. net weight | KGS | 2500 |

| Approx. machine size (L×M×H) | mm | 2100×1700×1850 |

The above specifications and values are based on Gang-type CNC lathe.

If there are other optional devices, the specifications and values will be different.

All specifications, dimensions and design characteristics shown in this website are subject to change without notice.

Reference picture

Standard Accessory

Optional Accessory

All specifications, dimensions and design characteristics shown in this website are subject to change without notice.

Accessory

| MODEL |

Standard accessories |

Optional accessories | N/A

|

| A2-5 spindle | ● |

||

| 6" 3-jaw Hydraulic Chuck or Collet Chuck (choose one) | ● | ||

| Soft Jaw or 173E collet (choose one) | ● | ||

| Lighting device | ● | ||

| Tools and tool box | ● | ||

| Coolant system and chip basket tank | ● | ||

| Powerful coolant pump 1HP | ● | ||

| Base leveling block | ● | ||

| Tool holder for inner hole (I.D.Ø20) | ● | ||

| Tool base for inner hole (I.D.Ø20) | ● | ||

| No-material alarm indicating lamp | ● | ||

| Tool holder bush (I.D.Ø6,8,10,12,16 / O.D.Ø20) | ● | ||

| Gang type tool plate | ● | ||

| Auto lubrication system | ● | ||

| Upper tool holder 20口/Lower tool holder 20口/Twin tool holder 20口 |

● | ||

| Tool spacer (up / down) | ● | ||

| Voltage stabilizer | ● | ||

| Transformer | | ● | |

| Finished-parts collecting device | ● | ||

| Track type electrical chip conveyer | ● | ||

| Oil mist recycle device | ● | ||

| Closed air cooler | ● | ||

| 8-Position hydraulic turret | ● | ||

| Bar-puller (Auto link) | ● | ||

| CE specifications | ● | ||

| Finished-parts collecting device | ● | ||

| Finished-parts collecting device and conveyor belt | ● | ||

| Y-axis side milling device(4-tool)(ER-16) | ● | ||

| Y-axis side milling device(4-tool)(ER-20) | ● | ||

| Y-axis side milling & end face milling device(8-tool)(ER-20) | ● | ||

| Three shaft drilling & tapping device(B-axis) | ● | ||

| C-axis function with disk brake system | ● | ||

| Single shaft side milling device-Top(ER-25) | ● | ||

| Single shaft vertical type milling device(ER-20) | ● | ||

| Single shaft side milling device-Below(ER-20) | ● | ||

| Oil skimmer | ● | ||

| Syntec 22TA controller | ● | ||

| Fanuc controller | ● | ||

| Automatic tool measurement for turret | ● |

All specifications, dimensions and design characteristics shown in this website are subject to change without notice.