Video

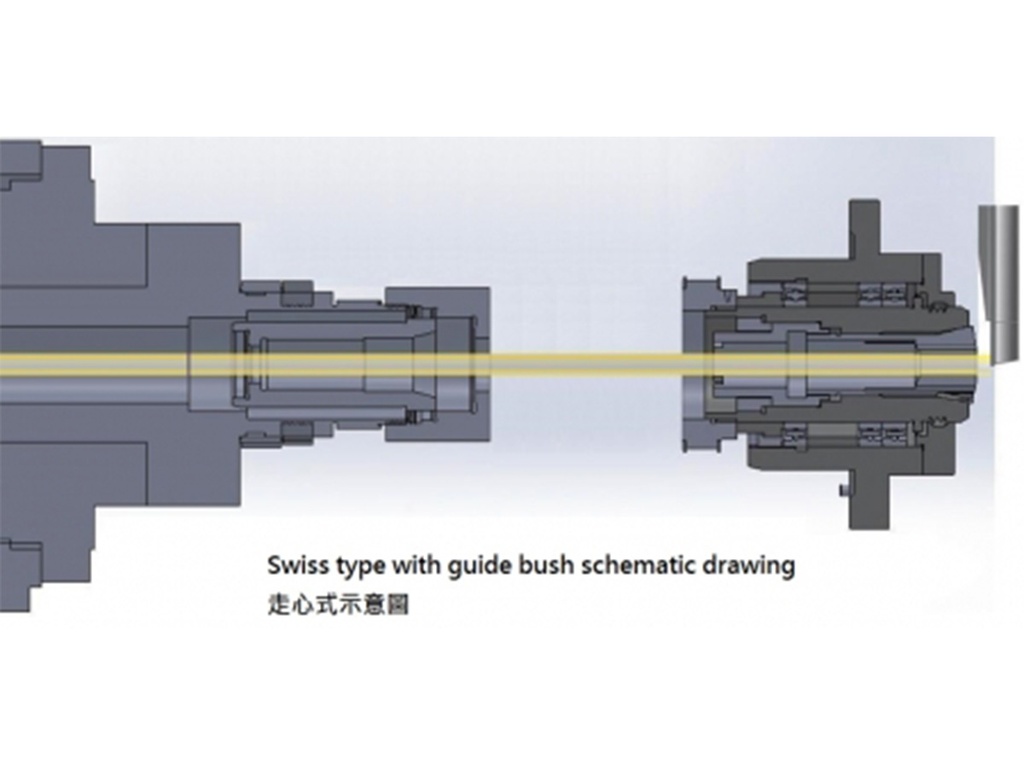

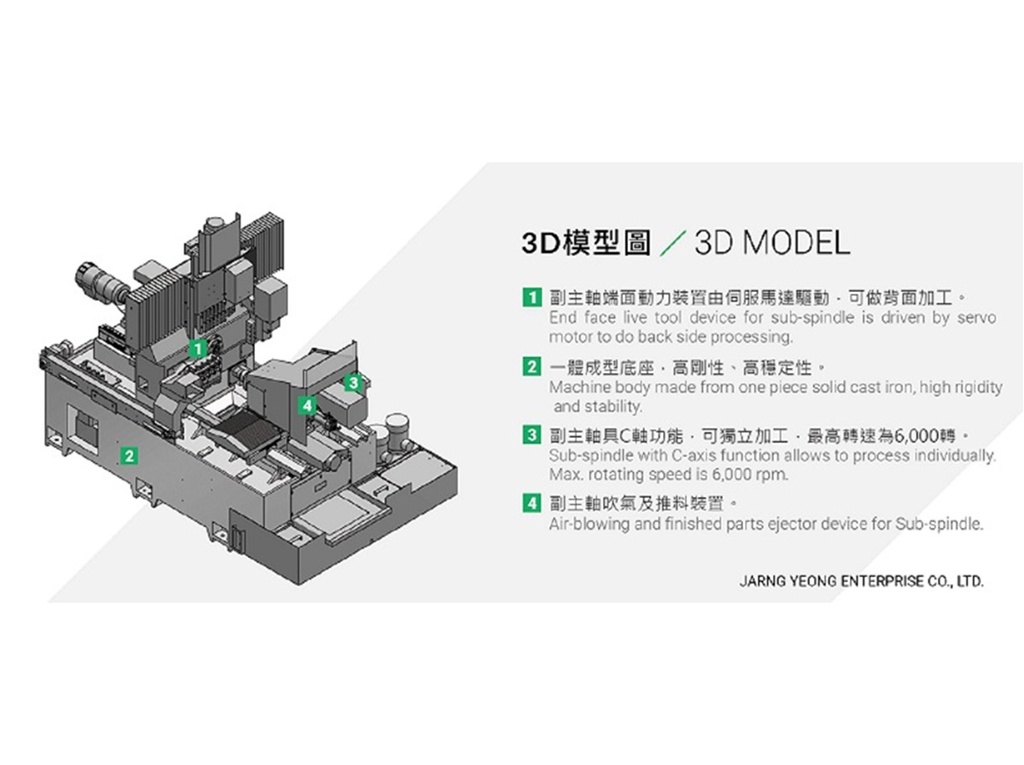

Taiwan Swiss type CNC Lathe HCS-25B/32B (sub-spindle;sliding head)

Specification

| MODEL |

Unit |

HC-25B |

| Max. turning dia. |

mm |

25 |

| Bore of spindle | mm | 28Ø |

| Spindle rotating speed | rpm | 6000 |

| Servo motor of built-in spindle | KW | 3.75(5.5opt) |

| X-axis travel | mm | 150 |

| Y-axis travel | mm | 420 |

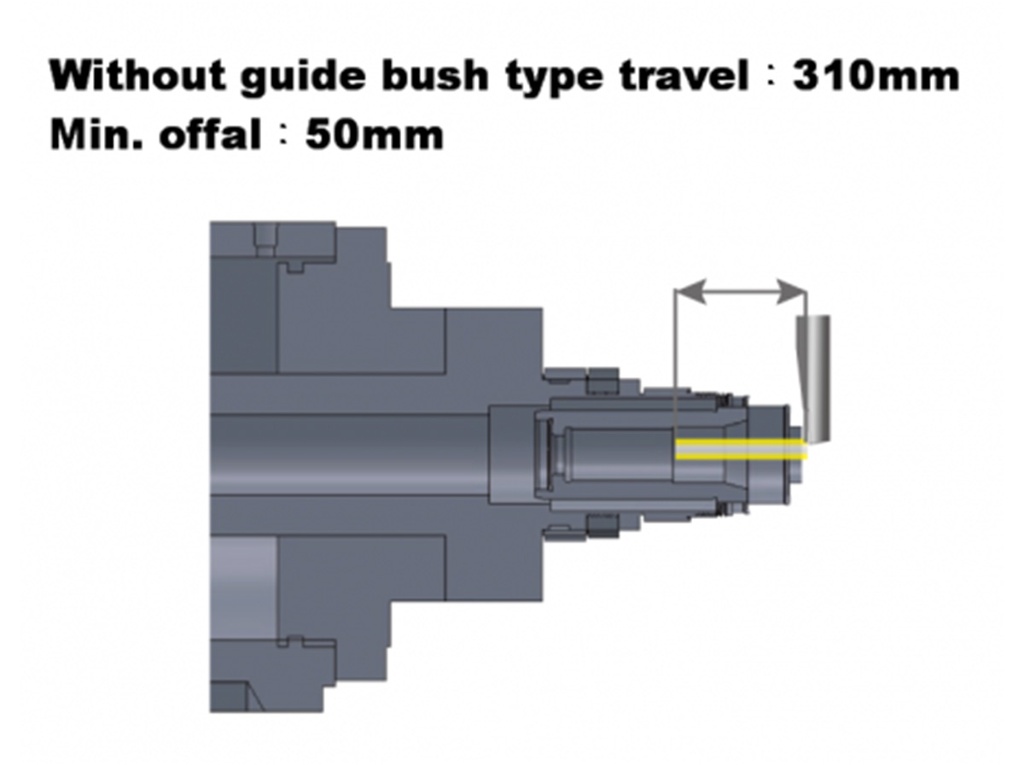

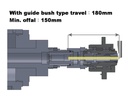

| Z-axis travel without guide bush | mm | 310 |

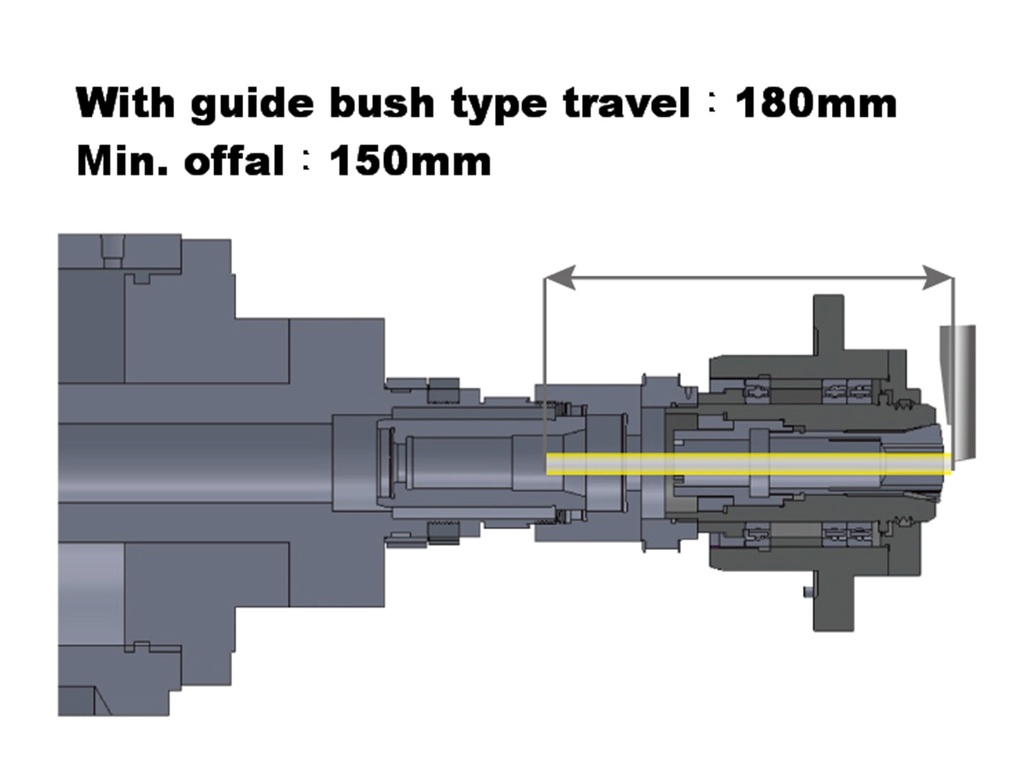

| Z-axis travel with guide bush | mm | 180 |

| X/Y/Z-axis rapid travel speed | m/min | 25 |

| X/Y/Z-axis servo motor | KW | 1 |

|

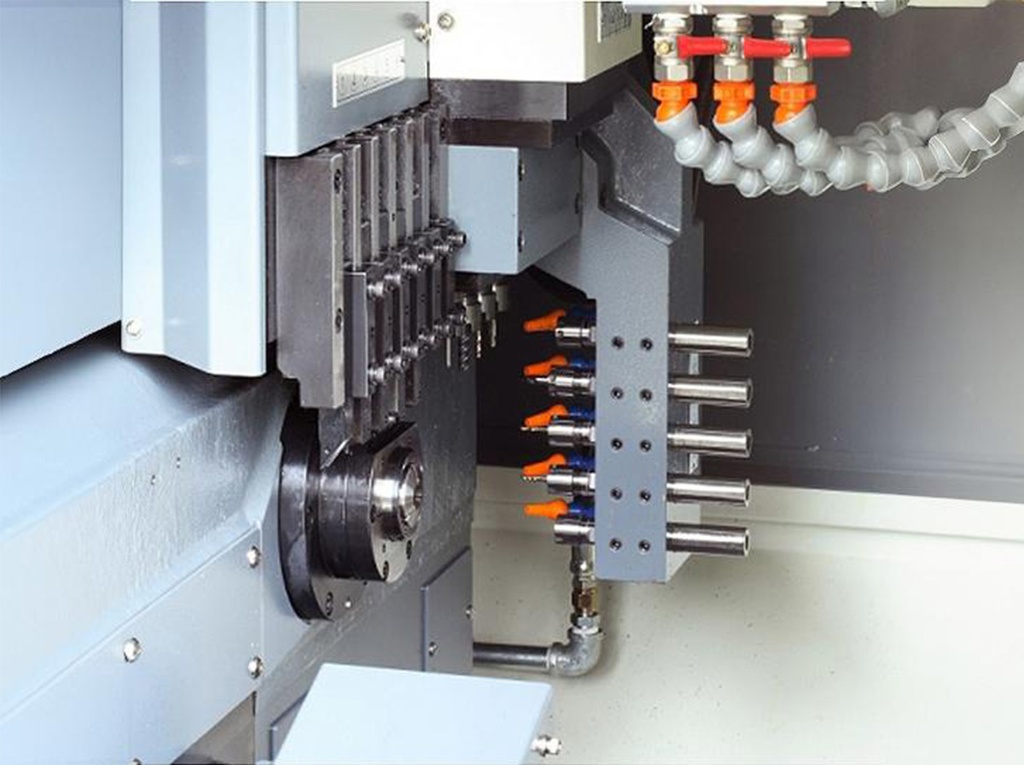

No. of O.D. turning tools | pcs | 6 |

| O.D. turning tool size | mm | 16□ |

| No. of I.D. turning tools | pcs | 5 |

| I.D. turning tool size | mm | 20Ø |

| Collet type | -- | Citizen 25# |

| Guide bush type | -- | Citizen 25# (opt) |

| Servo motor of live tooling | KW | 2 |

| Max. rotating speed of live tooling | rpm | 5000 |

| No. of side face live tooling | pcs | 4 |

| Size of side face live tooling | -- | ER-16 |

| No. of end face live tooling | pcs | 3 (opt) |

| Size of end face live tooling | -- | ER-20 (opt) |

| Cutting coolant volume | L | 150 |

| Cutting coolant pump | HP | 1 |

| Auto lubrication system | c.c/15min | 3~6 |

| SUB SPINDLE | ||

| Max. turning dia. | mm | 25 |

| Bore of sub-spindle | mm | 28Ø |

| Sub-spindle rotating speed | rpm | 6000 |

| Servo motor of sub-spindle | KW | 2.25 (3.75 opt) |

| X-axis travel | mm | 305 |

| Z-axis travel | mm | 240 |

| X/Z-axis rapid travel speed | mm | 25 |

| X/Z-axis servo motor | KW | 1 |

| Collet type | -- | Citizen 25# |

| Guide bush type | -- | Citizen 25# (opt) |

| Cutting coolant pump | HP | 1 |

| No. of O.D. turning tools | pcs | 1 |

| O.D. turning tool size | mm | 16□ |

| No. of I.D. turning tools | pcs | 4 |

| Size of I.D. turning tools | mm | 20Ø |

| Servo motor of live tooling | KW | 2 (opt) |

| Max. rotating speed of live tooling | rpm | 5000 (opt) |

| No. of end face live tooling | pcs | 4 (opt) |

| Size of end face live tooling | mm | ER-16 (opt) |

| Approx. net weight | kgs | 3000 |

| Approx. machine size (LxWxH) | mm | 2700×1600×2000 |

All specifications, dimensions and design characteristics shown in this website are subject to change without notice.

Reference picture

Standard Accessory

Optional Accessory

All specifications, dimensions and design characteristics shown in this website are subject to change without notice

Accessory

| Title |

Standard accessories |

Optional accessories | N/A

|

| Spindle collet |

● |

||

| Guide bush | ● | ||

| Main spindle oil cooling device | ● | ||

| 5 position end face drilling device (IDØ20) | ● | ||

| Lighting device | ● | ||

| 6 position tool holder (口16) | ● | ||

| Tools and tool box | ● | ||

| Parts catcher with conveyor | ●

| ||

| Coolant system and chip basket tank | ● | ||

| Powerful coolant pump 1HP | ● | ||

| Side face milling device for main spindle (4-shaft,ER16) | ● | ||

| End face live tool device for main spindle (3-shaft,ER20) | ● | ||

| Base leveling block | ● | ||

| C-axis function with lock | ● | ||

| Tool holder bush (IDØ6,8,10,12,16 / ODØ20) | ● | ||

| Built-in main spindle | ● | ||

| Auto lubrication system | ● | ||

| Voltage stabilizer | ● | ||

| Transformer | ● | ||

|

Electrical steel belt type chip conveyor | ● | ||

| Fixed-head type spindle block | ● | ||

| Synchronous rotary guide bushing device | ● | ||

| Spindle inner-hole bush | ● | ||

| Plug-type hand wheel | ● | ||

| Air-Condition unit for electric box | ● | ||

| Oil mist collector | ● | ||

| CE specifications | ● | ||

| Disc brake device for sub-spindle | ● | ||

| End face live tool device for sub-spindle (4-shaft,ER-16) | ● | ||

| 4 position end face drilling device (IDØ20) for sub-spindle | ● |

All specifications, dimensions and design characteristics shown in this website are subject to change without notice.